Speed up your quality checks from any device with the App Platform

29 Jul 2021

4 min read

What is the temperature in the truck? Did anything suffer damage? Are the pallets in a decent state? Besides registering orders and stock, chances are you also need to check the quality of your orders. To make sure traceability is possible to batch-, carrier-, or sometimes even to article level. And you know: traceability is necessary to guarantee quality. Therefore, your customers are strict when it comes to traceability and quality.

Eliminate manual actions and improve quality controls

In many warehouses, these quality checks are still registered on a

paper sheet. The (un)loaders check incomin orders on a clipboard with a

pencil and fill in values such as degrees Celsius. Why are they still

doing this with pen and paper? Firstly, in most cases, it concerns a

significant number of checkpoints. Secondly, because it is not always

easier to do it with a scanner. Keyboards are small and especially in a cold store gloves or cold hands do not improve fine motor skills.

These quality checks then need to be copied manually to your WMS. Also, do not forget to take pictures. Your customers or clients

demand proof. This can help you as well, by the way. These pictures need

to be transferred from the camera to the order or the ride. You might

feel it coming: this entire process can go a lot faster.

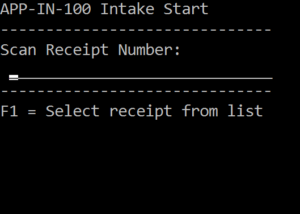

From pen and paper to our classic scan solution

That is why we offer a scan solution via a Telnet connection for years now. A stable technique, combined with a huge variety of standard functionalities. It enables us to create trustable and flexible processes. Users of this function can easily and efficiently register data concerning goods in-, goods out-, storage- and VAL-processes within the warehouse.

These processes are defined by scanning as much data from barcodes as possible. Think about order numbers, pallet numbers, location numbers, and so on. The more you scan, the less you have to write down on a sheet of paper and then enter it manually in your system. Another aspect of these scan processes is the limitations of choices and clickable moments. Why? To reduce the error margins to a minimum. We realize this by showing everything on simple screens on RF scanners. Saving you a significant initial investment compared to high-tech scanning equipment.

Example Telnet Scanning

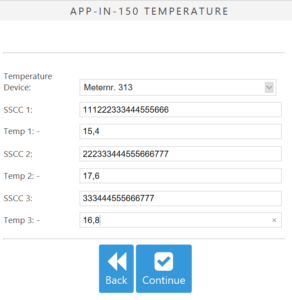

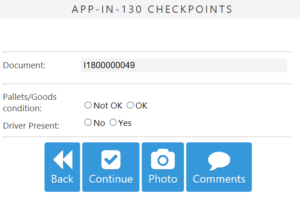

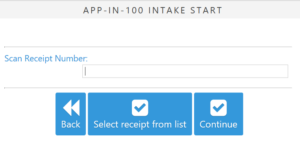

Scanning via the App Platform: the next level

Next to the beforementioned scan solution, our Boltrics (the developer of the solution 3PL Dynamics) offers for not too long now scanning via the App Platform. With this technique, we show the processes on a web browser. Making it is possible to use the technique on scanners but also on your smartphone or tablet. Creating new possibilities. Your touchscreen works like you are used to. Drop-down menus, clickable multiple choice answers, and buttons create more clarity than choosing by using function keys on a keyboard. Also, you can easily take photos with your phone or tablet and upload these directly to Dynamics.

Examples scanning via the App Platform

Top 3 advantages of the App Platform scanning functionality compared to Telnet Scanning

The App Platform uses the same functions as regular scanning en consists of the same scan function as the classic method. This way, Boltrics can easily configure these processes based on proven technology. The App Platform distinguishes itself from the classic scan function in the following situations:

- Quality checks with many checkpoints;

- Employers need to take pictures and add these to a document;

- A truck driver needs to sign a document.

- The signature can be drawn on the touchscreen and can be added as an image.

You (s)can do it!

In what way you designed your logistics processes, with 3PL Dynamics, we can offer a fitting scan solution for any situation. No more pen and paper, no more doctors’ handwriting, and double registration is in the past. Contact us and together with you, we will determine how you can optimize your processes.